BRIEF

Rethinking how we consume shoes.

[ Bachelor's Thesis ]

The culture of consumption within the fashion industry is rapidly developing towards more accessibility, as customers demand affordable and frequent updates to their wardrobe. Meanwhile, brands are pressured with presenting sustainable concepts and ensuring fair production.

MODi presents an exemplary product line, which aims for more sustainable interaction with footwear use and consumption.

AUDIENCE

Who are we designing for?

This project focuses on young adults in urban areas, as this is where the influence of trends, as well as the need for self-expression, is highest.

The desired target audience is further sectioned into Young Urbanites, Tastemakers and Practicalists, to better research and prioritize the users' needs and incapsulate lead-users, newcomers and the mainstream equally.

FINDINGS

What are their needs?

Following hour-long interviews with three different individuals, stemming from varying backgrounds, ages, incomes and residency, key frustrations and wishes regarding footwear could be extracted.

.

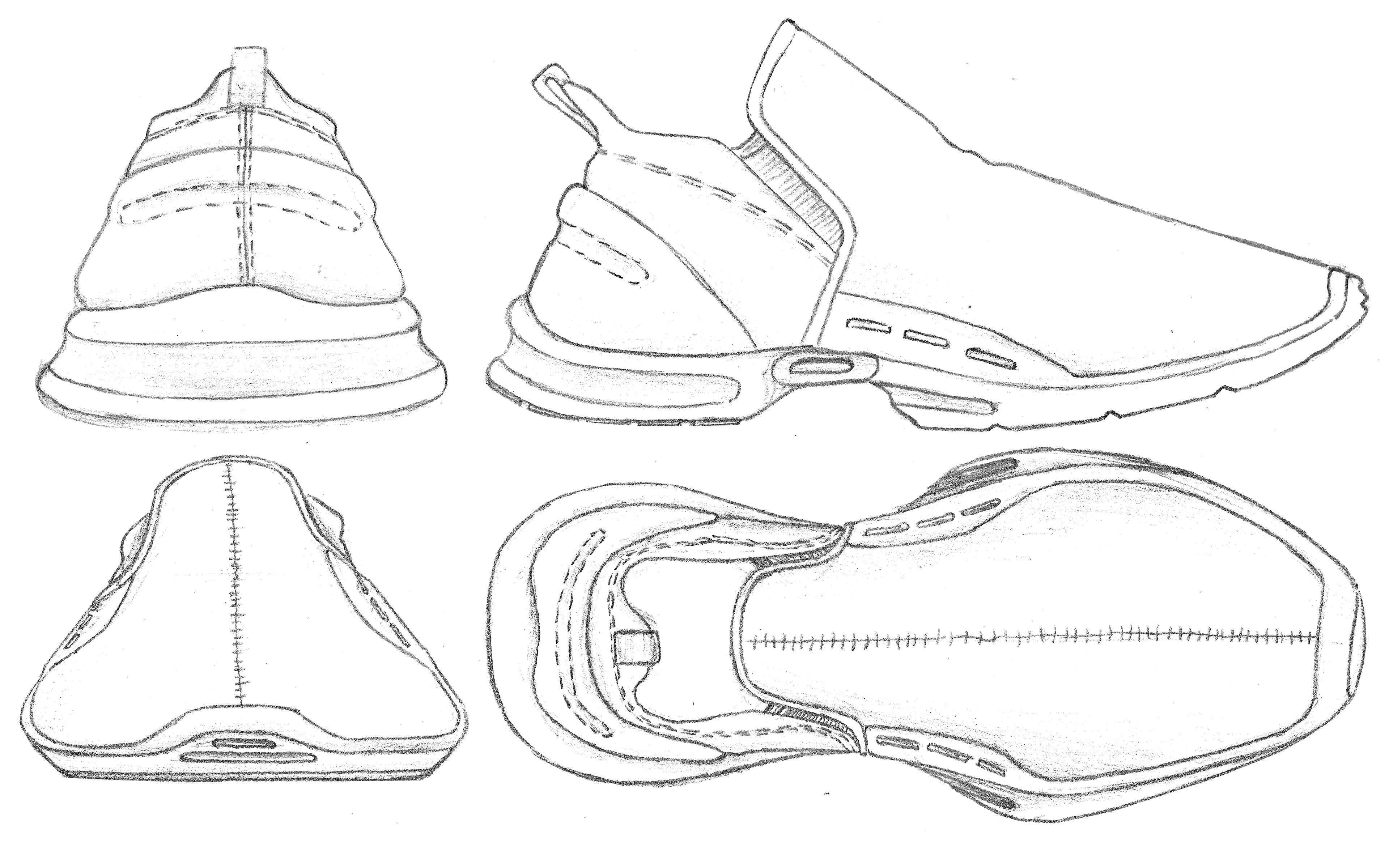

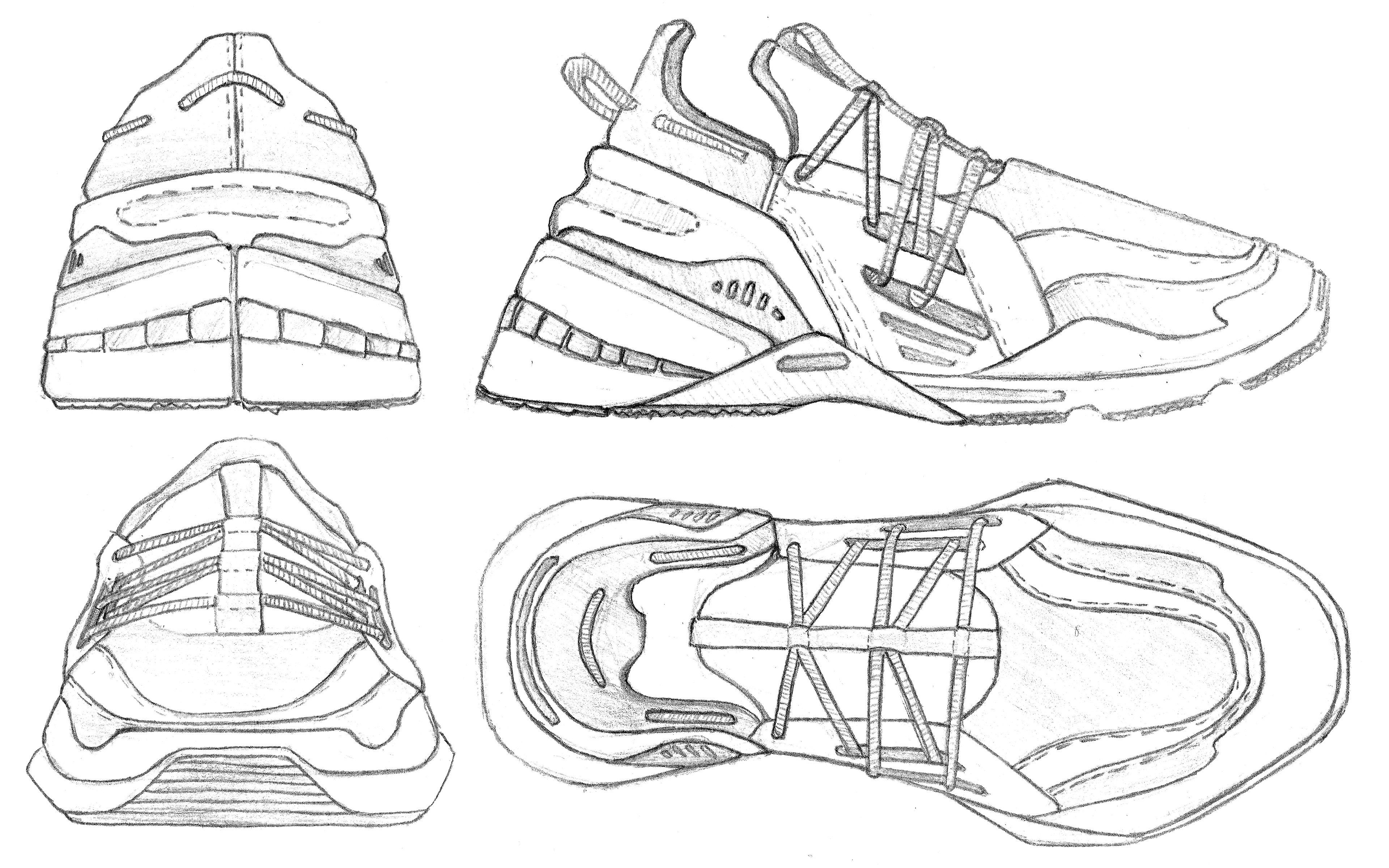

IDEATION

How do we solve them?

[ 01: Print your Soles ]

The first concept enables the user to print their soles at home, with a bought or rented 3D printer. The materials and uppers are sold separately.

[ 02: Care and Repair ]

Concept number two would try to make repairing and restoration more appealing by introducing workshops and various kits, each catering to a different type of shoe, with which the user can easily repair their shoes themselves.

[ 03: Mix and Match ]

The last concept aims to achieve more sufficiency through a modular concept. Instead of buying a whole shoe every time your old ones are worn-out or you simply want to expand your collection, you can buy soles and uppers separately.

Therefore, the most prone to failure part can be replaced. On top of that, the modules being interchangeable, different combinations offer more flexibility with styles and walking properties.

ANALYSIS

Sneakers deconstructed.

Due to the materiality and the architecture, a separation of the outsole is possible. This allows for the most vulnerable part to be replaced, as well as variation in the running characteristics and the profile.

The midsole and upper should be firmly connected, with the midsole serving as the connection point to the outsole.

The insole is still separate but should be transferable to different uppers so that orthopaedic insoles can be used.

The insole is still separate but should be transferable to different uppers so that orthopaedic insoles can be used.

Prototype

Does it work?

To validate the concept, a rapid prototype was made from simple materials of low complexity. I cut and glued EVA foam sheets to replicate the midsole and glued the overhangs into a conventional outsole.

Due to the materiality, only minor testing was possible, but it turned out promising.

A polyurethane prototype was in the works, but unfortunately, the moulds melted while drying in the sun from wet-sanding. Due to time and financial constraints, they could not be completed.

Lifecycle

How do we achieve circularity?

Users are offered shoe combinations of different uppers and soles to make the selection easier.

In the following step, they are then shown the individual uppers and soles that were included in the combinations. The modules can be freely combined with each other.

In the following step, they are then shown the individual uppers and soles that were included in the combinations. The modules can be freely combined with each other.

After confirming the selection, the purchase can be completed. The modules are then shipped or collected in stores.

If a module is eventually disliked or worn out, it can simply be returned. The module will then be restored or recycled, depending on its condition.

If a module is eventually disliked or worn out, it can simply be returned. The module will then be restored or recycled, depending on its condition.

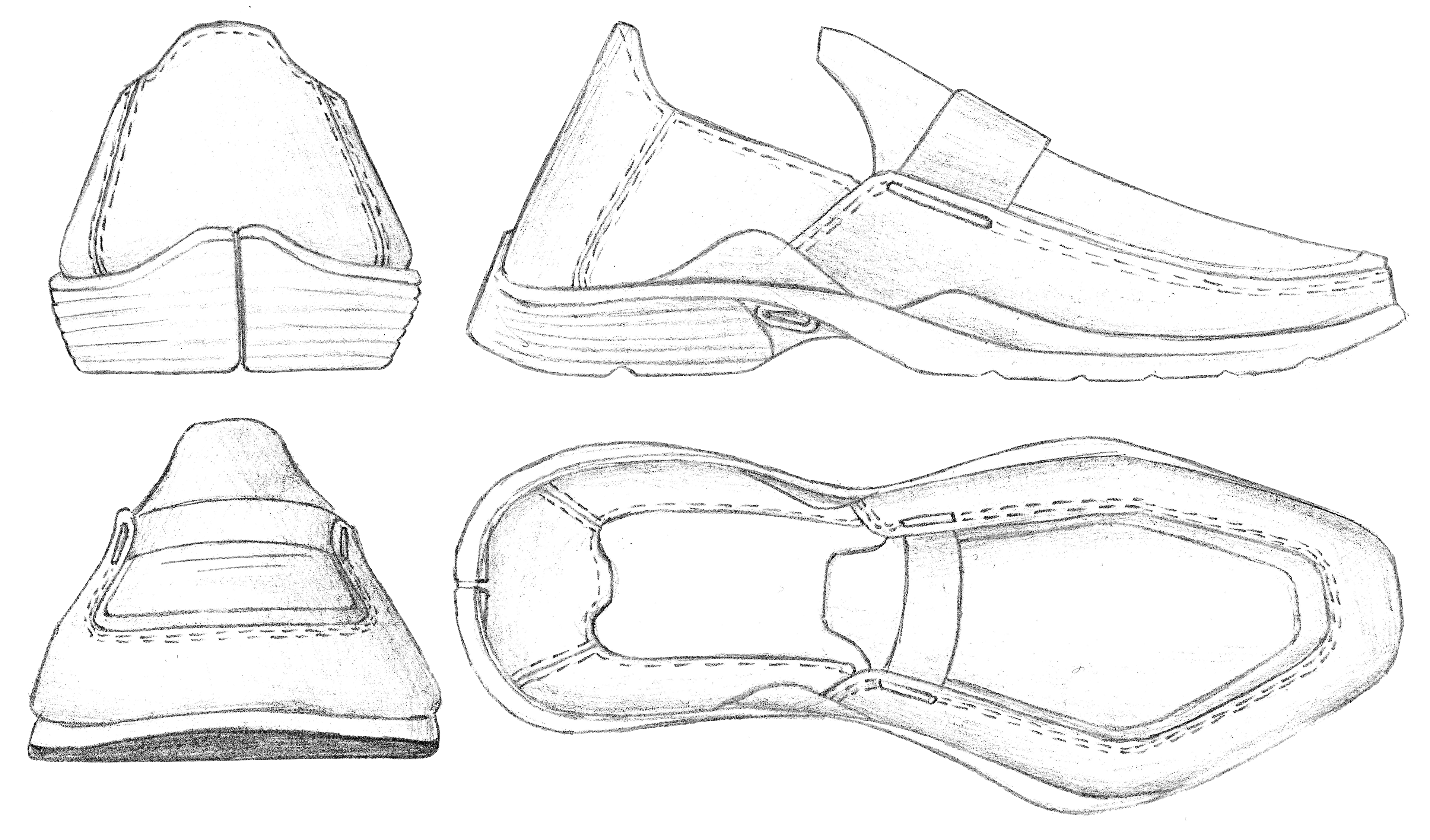

Design

What do they look like?

To show the potential for variation in MODi, I defined three archetypes of sneakers to cover a wide range of different styles and environments.

These archetypes also infer from the megatrends and personas and include casual sneakers, smart sneakers and hype sneakers.

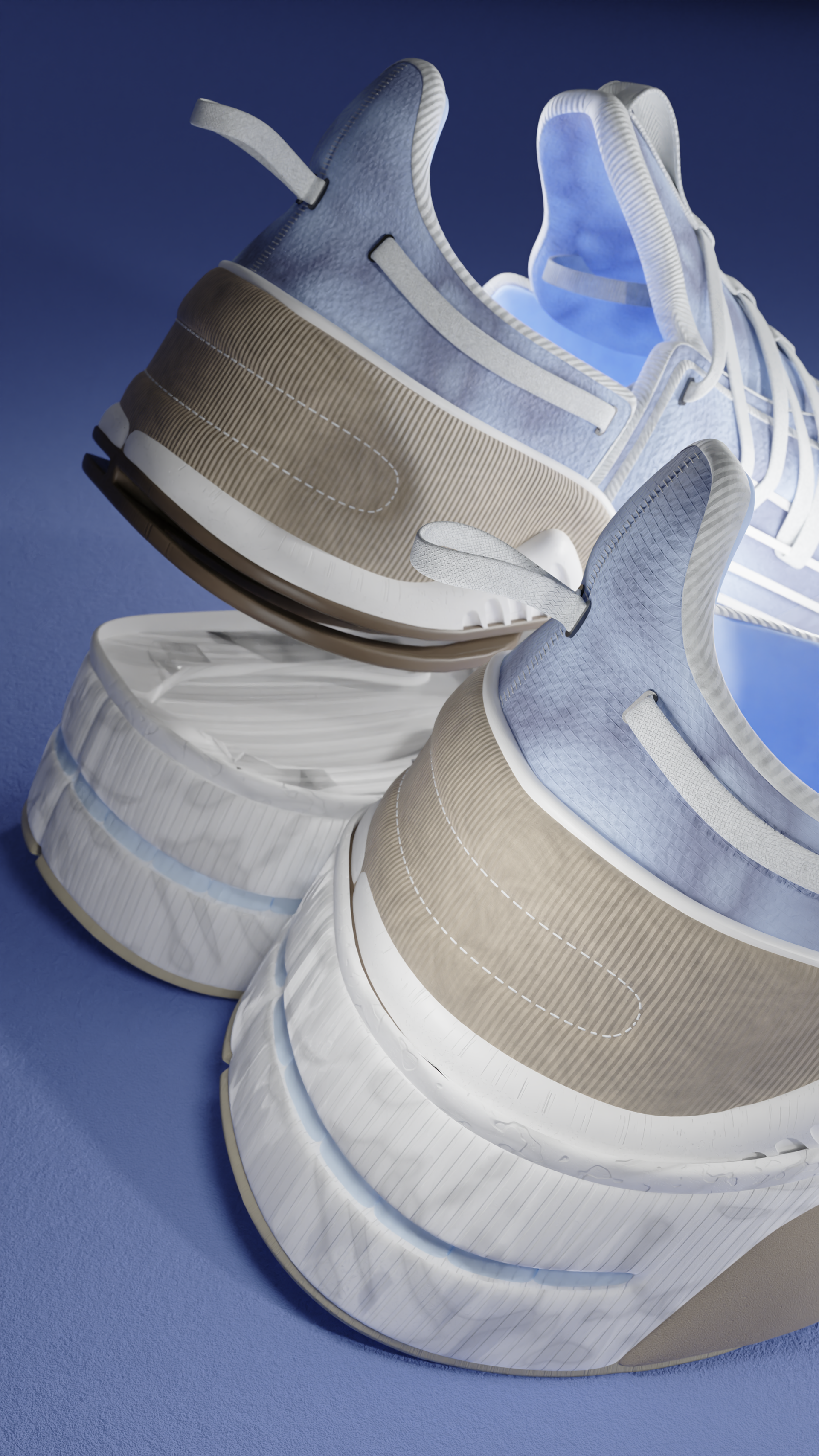

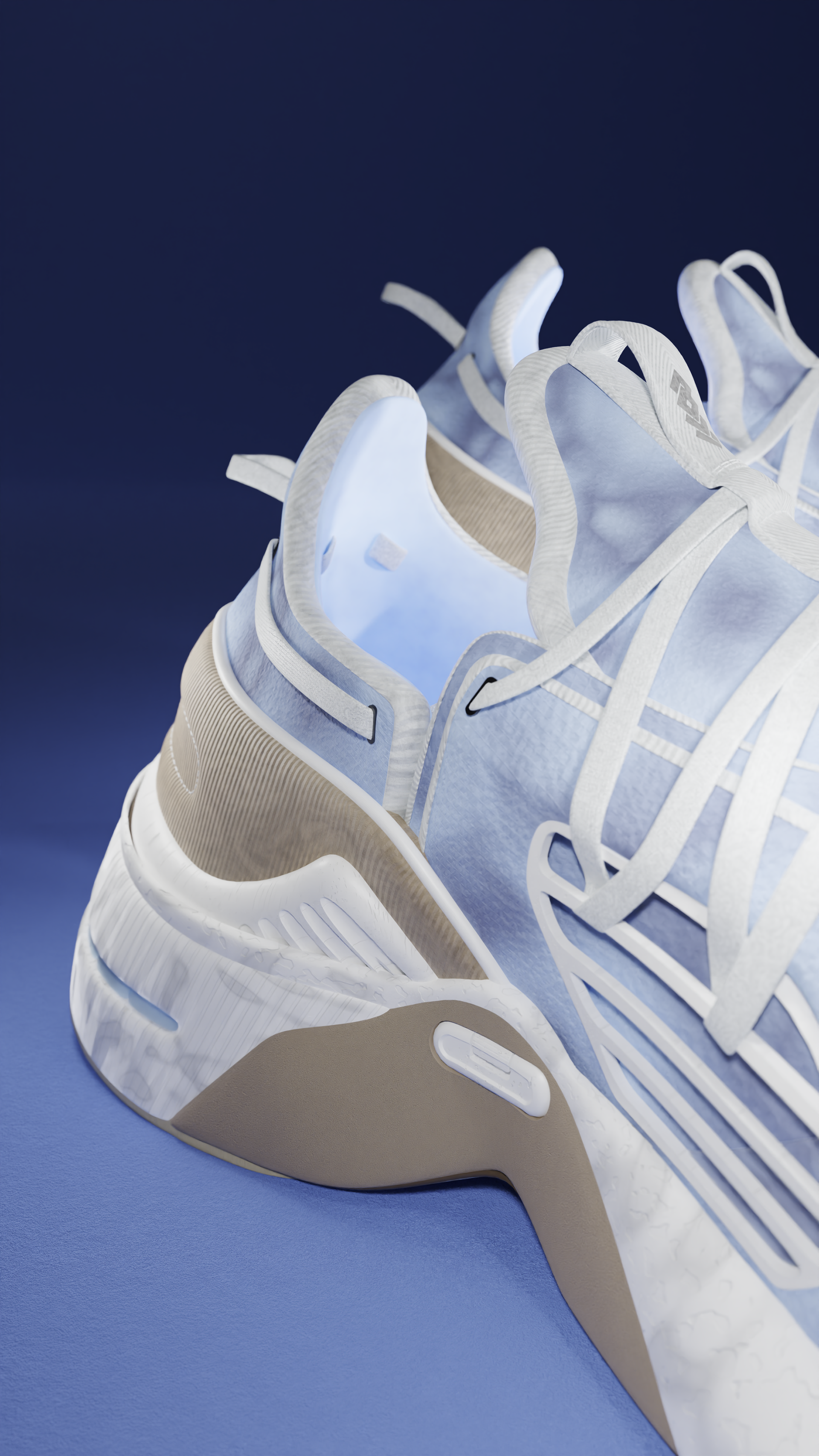

Renderings

Selected Colourways.

Concluding the design, the shoe series is featured in a selection of different colourways. As it was rather difficult to create a unified series the more colours came into play, the colourways are better adjusted within their series – while they can still be combined with modules from others.

The renderings and models emerged from a combined workflow between Solidworks and Blender, relying on Blender for most tasks. Textures and materials were all custom-made, simulating real-world materials, dyes, prints and composites.